Epoxy flooring – wide application in plants and public utility points. Why is it so popular?

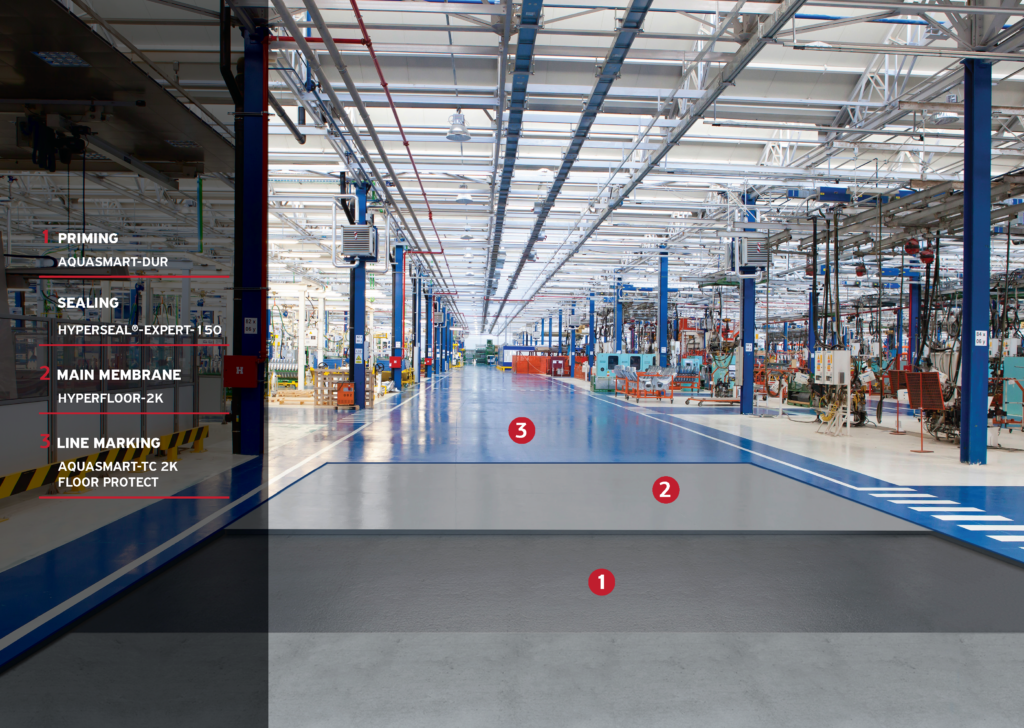

Epoxy flooring is often interchangeably called simply resin flooring . This is not entirely correct, because resin surfaces are a multitude of specific types. One of them is epoxy flooring . This type of surface is nothing more than a two-component substance with polymers, which consists of synthetic resin and hardener. This material strongly binds with the substrate, creating a strong coating. Epoxy flooring as a finish for concrete, reinforced substrate is usually used in commercial facilities such as: shops, galleries, railway stations, schools, offices, warehouses, production halls, offices, hotels, etc. Such a wide range of applications is the result of the solidity and durability of the epoxy surface, especially on:

- increased traffic of people;

- intensive traffic of vehicles, forklifts, etc.;

- chemical factors, e.g. in manufacturing plants using such factors;

- mechanical factors – impacts, falls;

- liquid absorption;

- thermal factors, temperature, UV radiation – although in this respect polyurethane resin flooring has better properties.

How to prepare a substrate for an epoxy floor? What is worth knowing?

Laying an epoxy floor requires professional knowledge and skills in the scope of – firstly – the selection of materials, and secondly – knowledge of the appropriate, required conditions and method of its installation . The thickness of the concrete substrate should be suitably reinforced and thick for the expected intensity of pressure. The concrete cannot have any breaks, gaps, cracks and must be evenly laid. All dust, loose elements must be removed. The existing concrete should be washed, degreased and possibly filled. You can also lay a self-leveling cement mortar. A new layer of concrete must be ground after its maturation period. A primer layer is necessary each time.

Epoxy flooring can be additionally colored with any color from the RAL palette or remain transparent with the addition of e.g. sand, aggregate, pieces of mirrors, flakes or stones (the so-called wildly fashionable stone carpet for a terrace or balcony). In this way, true masterpieces, 3D floors can be created – used in luxurious and original interiors.

What else is worth knowing about epoxy resin flooring – the most important issues

Epoxy flooring in short is also :

- minimalist and industrial effect;

- seamless surface, easy to keep clean;

- excellent and durable surface for plants, factories, workshops, halls, schools, etc.

- increasingly frequent use in private rooms (in this case, polyurethane resin floors are more often used than epoxy floors);

- possibility of varnishing: gloss, satin, matt;

- comfortable floor, suitable for allergy sufferers;

- can be placed on “bare concrete” – important for construction projects;

- a very good solution for underfloor heating.