Industrial flooring – what types are available on the market?

When faced with the choice of appropriate industrial floors, it is good to know what we can choose from. Depending on the purpose of the facility, a different type of floor may turn out to be the most appropriate option. The most popular are concrete floors characterized by great resistance to bending and compression. Various mixtures of materials are enriched with other anti-shrinkage agents, which additionally increases their durability and the associated reliability. Cement-polymer industrial floors are made from a mixture of special cements, fillers, reinforcing fibers, and other admixtures . Their main features include impact resistance and heavy wheeled transport. When it comes to resin floors , their binders are epoxy, polyurethane, acrylic, vinyl-ester, epoxy-polyurethane resins. One of the possibilities is the Rubber Binder M20 polyurethane resin offered by the Alchimika brand, which can be used, for example, as a sports surface . The last type of industrial floors are those classified as ceramic, i.e. made of smaller tiles glued to the substrate using mineral or epoxy adhesives.

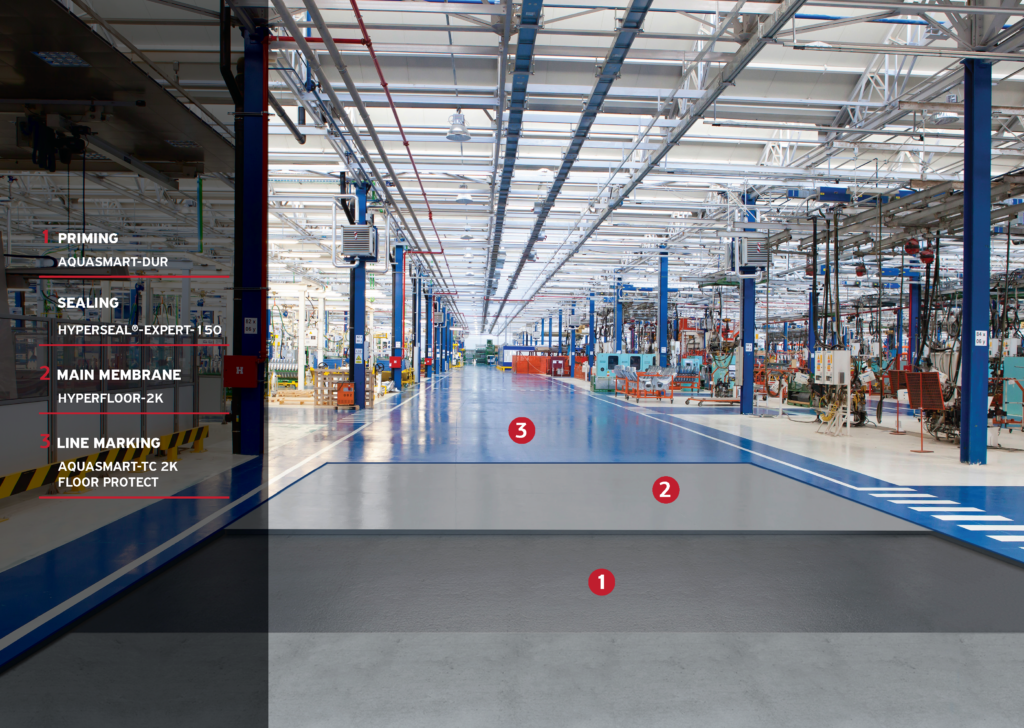

What do properly designed industrial floor layers look like?

In the case of industrial flooring, layers laid correctly are extremely important . Thanks to the correct design of the floor, we can be sure that it will serve us for a really long time. A typical scheme of laying industrial floors makes it clear how the surface should be built. The first element is the ground substrate. Then comes the time for substructures, as well as a slip layer and a possible separation layer. Next in line is a concrete, reinforced concrete or steel fiber reinforced slab. The last part is a properly shaped and prepared top layer. An example of an industrial floor is the Hyperfloor 2K polyurethane floor offered by Alchimik. It consists of a primer, the floor itself, and a protective top-coat. Solidly made industrial floors will serve with reliability and great durability, which make up their undoubted advantages .

What features do industrial screeds meet?

In addition to floors, we can also opt for industrial screeds . This type of floor is gaining supporters, among other things, due to its durability. We distinguish several variants available on the market. Thin-layer cement-polymer screeds are characterized by relatively high resistance to loads, the possibility of choosing a color, or the fact that they are suitable for renovated facilities. When it comes to industrial screeds based on epoxy resins, they meet aesthetic properties, what’s more, it is possible to make a floor with an anti-slip structure . Decorative polished screeds also seem to be an interesting option. They are similar in appearance to granite or marble, and give a mirror effect and are easy to keep clean. The variety of available industrial screeds means that we have the chance to fully adapt the facility to the needs it will have to meet . A wide range of possibilities is guaranteed by the Alchimika company, so it is worth getting acquainted with the solutions they propose. The final decision made regarding an industrial building must guarantee us that the floor will be solid and durable.